Our Impact

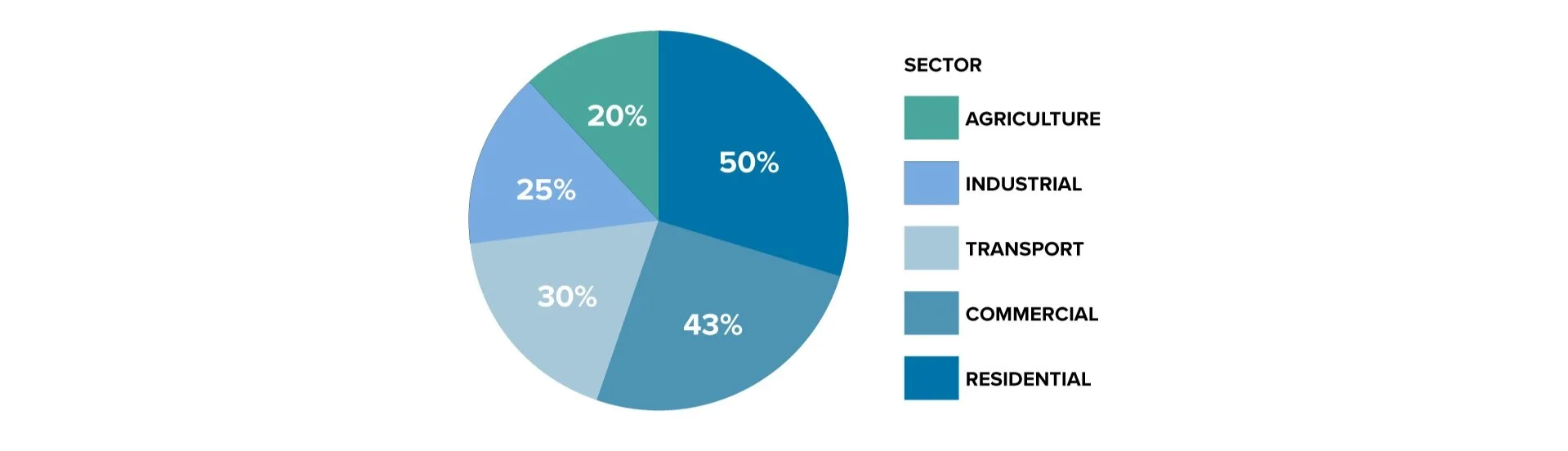

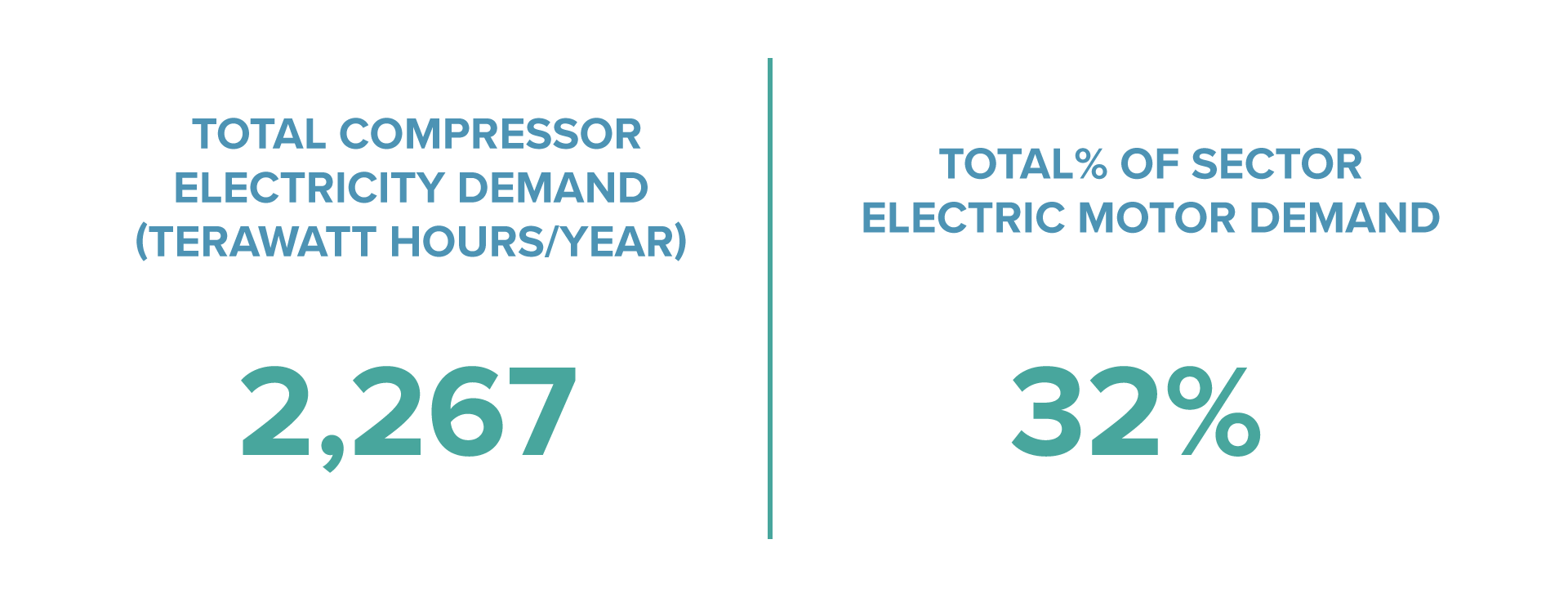

Carnot’s technology addresses a very significant global energy challenge. In the United States, industrial air compressors consume over 12% of manufacturing electricity consumption, or 399 trillion BTU. Globally compressors driven by electric motors are estimated to consume 32% of the electricity consumption from electric motor driven systems, or 2,267 Terawatt Hours Per Year in 2006.

At $0.10 per kilowatt hour, this translates into nearly $227 BILLION OF ANNUAL ELECTRICITY COSTS FOR COMPRESSION.

Commercial & Social Impact

$227 Billion of annual electricity costs for compression. Carnot’s mission is to reduce these costs by 20% or more.

Compressor Electricity Demand (Terawatt Hours/Years)

% of Total Sector Electric Motor Demand

Source: Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems. International Energy Agency. 2011 Working Paper, Waide and Brunner.