Carnot Compression Announces successful testing of proprietary isothermal compression behavior

Carnot Compression Inc. announced it has successfully demonstrated isothermal compression (i.e., temperature remains constant, ΔT = 0) across multiple tests and design iterations. Carnot says its results represent a major breakthrough in energy efficiency for the compression industry; prior to Carnot’s technology, the Taylor Compressor, implemented at the beginning of the 20th century, was the only isothermal compression system in operation, the company says.

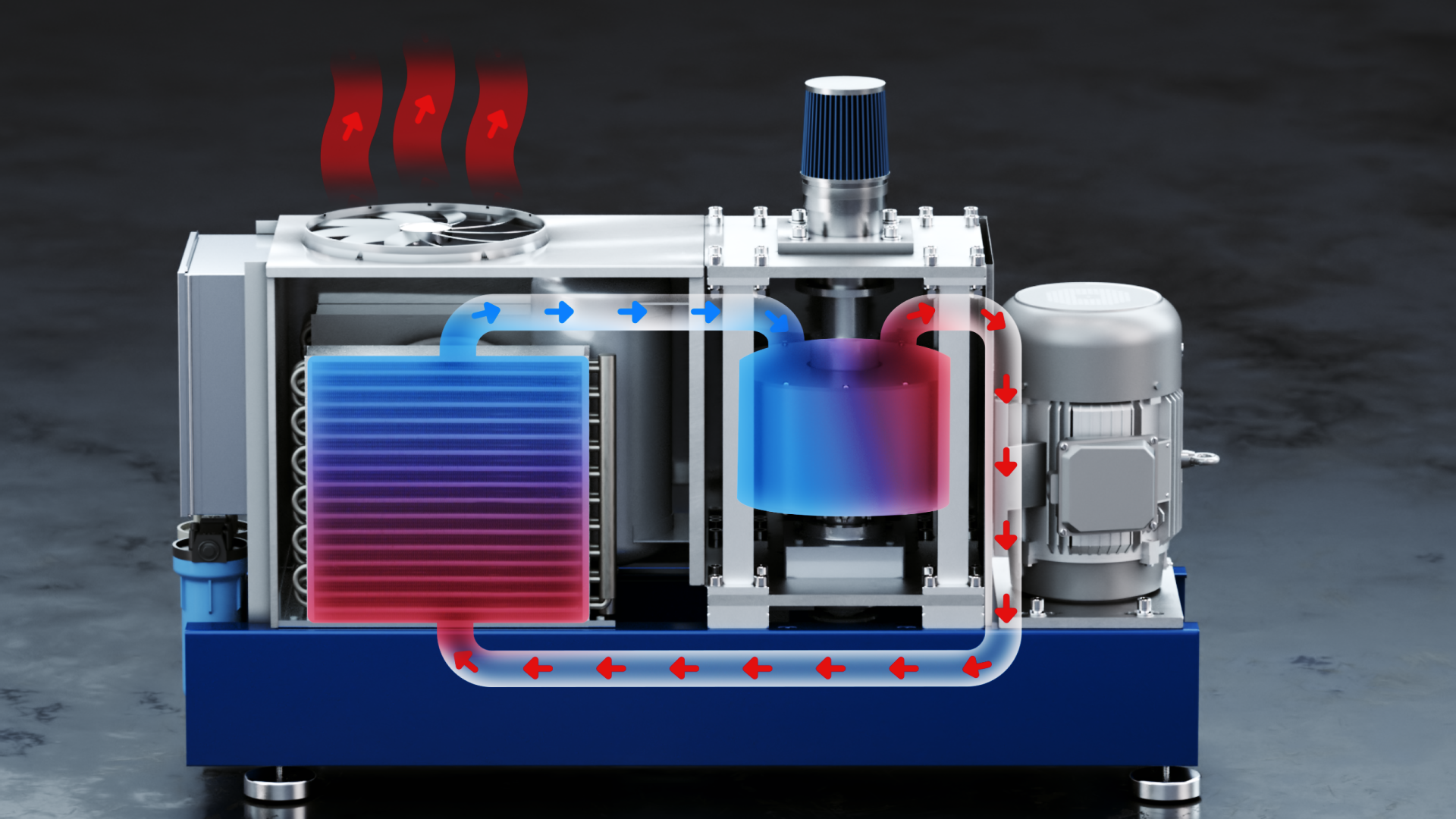

Carnot designed and built a novel centrifugal compressor utilizing the weight of water to compress gas with a proprietary impeller; Carnot’s surface area ratio and the thermal capacity of water enables isothermal compression. Carnot’s process uses a gas/water micro-emulsion to compress gas in a centrifugal field. Water absorbs the heat of compression. Therefore, Carnot’s process requires less energy input to deliver comparable compression output versus conventional compressors.

Carnot’s proprietary process creates millions of tiny gas bubbles surrounded by water. The thermal capacity of water is 3,500 times that of air. Water absorbs all the heat of compression.

Carnot’s ratio of water surface area/gas bubbles has absorption capacity of ~7500 watts of heat energy, or more than 1800 times what is necessary for isothermal compression.

Moisture and water soluble gaseous constituents in bubbles are absorbed through the compression process, eliminating the need for dryers and other after-treatment equipment.

Carnot’s compression system takes a mixture of gas and liquid at any temperature and combines them as an emulsion when entering the compressor. The rotating compressor uses centrifugal force to shrink the bubbles, compressing the gas inside them as they move from the center of rotation to the outside of the compressor casing, where they are allowed to collapse as they join together in a pressure chamber. This single stage compression cycle not only compresses the gas up to 200 times the entry pressure while maintaining the entry temperature (isothermal), it also dries the gas to levels beyond most industry requirements.

Prior to Carnot’s breakthrough technology, true rapid isothermal compression existed only in theory. Micro-Emulsion Bubble compression in a centrifugal field will enable a revolution in any industry that relies on compression.

—Mark Cherry, Co-Founder and Chief Technology Officer

Carnot’s technology could drive energy and cost savings across a broad base of compression applications including industrial air compression; multiple oil and gas compression applications; CNG fueling; refrigeration; HVAC, energy storage; and more.